MOTORS, MOTORMOUNTS & LINESHAFTS

Belt and Pulley fans:

Motor Mounts:

Belt and pulley systems are unique in that they have a single motor to power a number of fans. Woolen Mill fan motor mounts are strictly wall mounted with the pulley at the same level as the pulley on the first fan. Also two pulleys can be placed on the motor mount to drive two sets of fans in different directions. In special cases a coupler to drive a vertical line shaft for fans at various levels can replace the pulley.

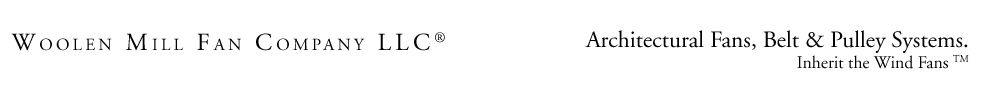

There are two motor mounts that are available; the “L” bracket is the simplest and least expensive with two heavy-duty bearings, stainless steel shaft, slip clutch sprocket to prevent backlash and a quiet plastic chain that requires no lubrication. This bracket is only available as a vertical mount and allows for one or two pulleys.

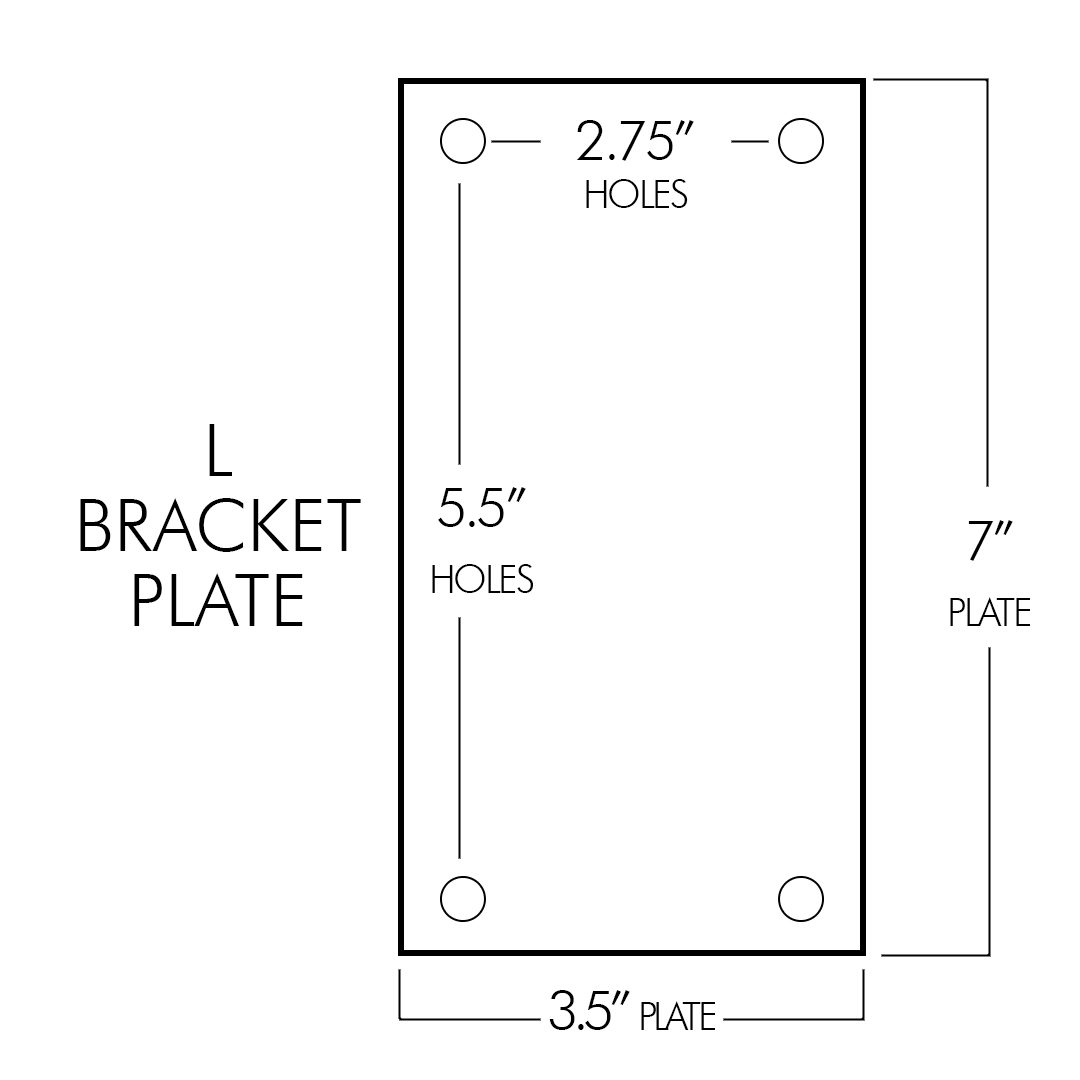

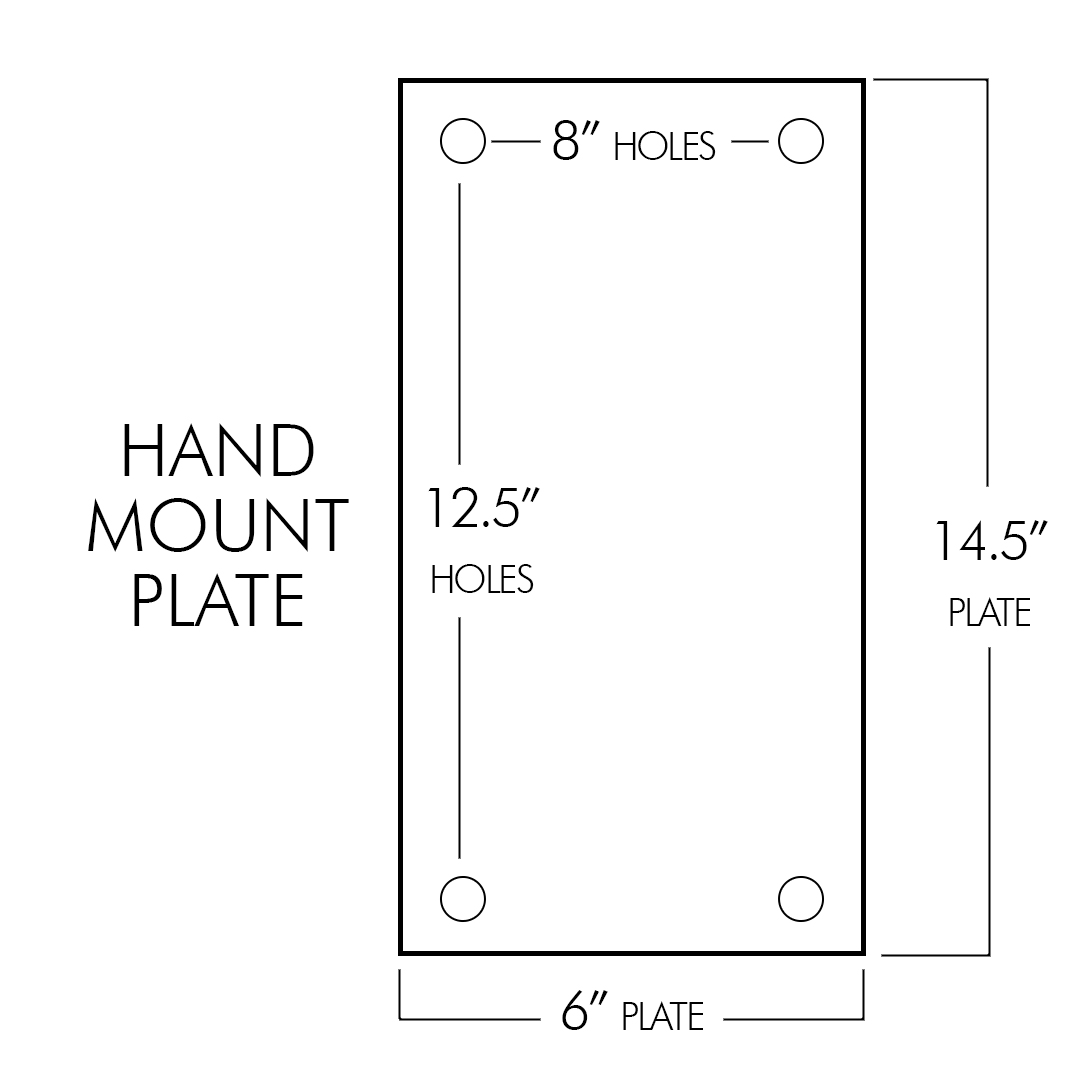

The “hand” motor mount has a cast patina aluminum hand to hold the bearings and stainless steel shaft with the same slip clutch sprocket, plastic chain arrangement as well as a metal chain guard. The hand mount can also hold one or two pulleys and is available in a vertical and horizontal mount arrangement.

Hand Held Horizontal Mount

The mount consists of the rectangle back plate with the hand sculpture.

Hand Held Vertical Mount

Optional hand-held motor mount shown with the Bodine 2272 (front & side views).

Other motors that can be used with this mount include 0098 and 2294.

Motor shown with pulley.

Motors and Controllers:

>NOTE: All motors and controllers require regular 110v AC electricity!!

(International 220v and 3 phase input is available by special order)

After selecting the style motor mount we need to size the proper motor to drive the number of fans in the system. All of the motors listed fit both of the motor mounts described above. Bodine motors are built in the U.S. as high-end industrial motors and are selected for their superior durability and are virtually silent. All of the motors require regular 110v input into the controllers (included) that changes the electricity into either DC or 3phase AC depending on the type of motor selected. You should have a designated 110v circuit for the controller. International motors requiring 220v input are available.

- For residential applications the 0096 DC motor is the least expensive motor that will run 1 to 3 fans up to 100 RPMs. Since it has brushes they may need to be occasionally but easily replaced. The included controller is the 0790 which is UL recognized and converts regular 110v Ac current to DC required by the motor.

- For residential and commercial applications to run 1-5 fans the Bodine 2294 is an exceptional choice. The included Eaton drive converts regular 110 Ac current to 220v 3-phase current and is UL Listed. An international 220 input version is available.

- For commercial and residential applications to run 5-10 fans the Bodine 2272 motor is required. This motor can also be used on smaller fan systems without a motor mount however the cooling fan maybe noticeable in residential applications. The included Eaton drive converts regular 110v AC current to 220v 3-phase current and is UL listed. An international 220v input is available.

Bodine Variable Speed

Model 0098

DC Motor / 2 Wires + a Ground to Motor

/ Quietest Motor for 1-2 Belt Fans

- Uses 0790 Controller

- AC Single Phase Power to Controller

- Variable Speed

- Speed Pot Adjustment Knob with On/Off Switch Mounted in an Enclosure

- Download Controller Manual PDF

- Product Description on Bodine Website

Bodine Variable Speed

Model 2272

AC Motor / 3 Wires + a Ground to Motor

/ Up to 10 Fans

- Uses AES-AC-100 Controller

- AC Single Phase Powerto Controller

- Variable Speed

- Very Quiet

- Digital Speed Adjustment with Digital Read-Out

- Includes Wall Mount Enclosure

- Download Controller Manual PDF

- Product Description on Bodine Website

Pacesetter 30R-3N Right Angle AC Inverter Duty Gearmotor Model 2294

AC Motor / 3 Wires + a Ground to Motor

/ Up to 5 Fans

- Three Phase, Inverter Duty

- Variable speed, 3-phase design

- 110V AC Single Phase Power to Controller

- Digital Speed Adjustment with Digital Read-Out

- All new optimized motor and gearhead combinations for maximum output power in the smallest package.

- Download Controller Manual PDF

- Product Description on Bodine Website

Direct Drive Fans:

The following fans models are available in a direct drive version; Peacock, Ostrich, Rhea, Emu, Cassowary, Small and large Kiwi, Large Ostrich. The direct drive versions require space above the ceiling as their motors are attached to the top of the wooden disks. The direct drive fan motors are small, 6in high and 4 in square and are single speed 100rpm, there is also a 60 rpm motor available. The fan body and blades are exactly the same ones used for the belt and pulley fans without the pulleys. These fans are sold complete with the fan body, blades, motor and wooden disk, options include the shaft length, finish and blade diameter. These fans are mounted by lagging them to a solid structure above the ceiling and while lags can be put anywhere on the wood disks the “cleanest” mounting is to have some framing above the fan legs (refer to each model’s unique footprint in “Design” page for the dimensions of the hole pattern). As with the belt and pulley fans the airflow can be regulated by manually tilting the blades.

Direct Drive Motors:

The new Oriental motors used in direct drive applications are virtually silent and retrofit kits can be purchased for earlier fans using the small Bodine motors. The 100 rpm motor is typically used but the slower 60 rpm motor can be installed which matches the earlier Bodine model. Speed control is not available and these motors will not drive belt systems.

Oriental Induction Gear Motor 21K6UA-18A

AC Motor / 2 Wires + A Ground to Motor / 6 Watt Motor for 1 Fan

- The next generation KII Series offers higher strength gears that maximizes motor performance with ease of use wiring and mounting.

- Higher Permissible Torque

- Long Life (Rated life 10,000 hours)

- Low Noise

- Combination Type (Motor and gearhead come pre assembled)

- Download Installation Instruction PDF

- Product Description on Oriental Motor Website

Oriental Induction Gear Motor 21K6UA-30A

AC Motor / 2 Wires + A Ground to Motor / 6 Watt Motor for 1 Fan

- The next generation KII Series offers higher strength gears that maximizes motor performance with ease of use wiring and mounting.

- Higher Permissible Torque

- Long Life (Rated life 10,000 hours)

- Low Noise

- Combination Type (Motor and gearhead come pre assembled)

- Download Installation Instruction PDF

- Product Description on Oriental Motor Website